I am not a potter, but I am very interested in pottery, particularly the low tech stuff where you win your own clay, process it, mould it into something useful like pot-in-pot coolers and then low temperature fire it without a kiln. I have won and processed my own clay but I need more practice in the forming and firing of it and I will write an article on getting your own clay to the point where you can make something with it. To get the clay to that point it is handy to have one of these plaster bats to make the job easier.

Organise yourself some moulds, preferably from things you have floating around, and they should slope outward so that when the bat is hardened you don’t have trouble getting it back out. Plaster is reasonably strong but if put under undue pressure it WILL break, especially when it is first cast, so make the job easier for yourself by setting it up right. For the outer mould I use one of my famous, cheap and mind bogglingly useful cat litter trays. The tray needs to be clean so it would be better to get one that you use for agricultural purposes rather than one regularly patronised by an actual cat. Otherwise you may have to go out and buy one.

Next you need an inner mould to make the depression in the top of the bat that you are going to pour the clay slurry into. I use a ceramic baking dish that my lovely partner in the sustainable life uses to make lasagne in, I just promise not to break it and clean it up after I have finished with it. Being ceramic, it has enough weight so that when I place it in the plaster slurry it floats at the right height to give me a good sized depression, otherwise you might have to hold it in place while the plaster sets. It also has walls on an angle so that it comes away from the plaster bat pretty cleanly, and because it is very smooth and shiny I didn’t need to use any release agent.

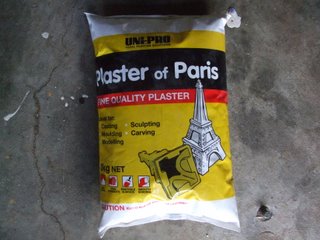

OK, so now you have your inner and outer mould organised, get hold of three kilograms of plaster of Paris from your local hardware store and a nine litre bucket to mix it in. If you put in 700mls of water per kilogram of plaster you intend to use it will give you the strongest, densest mix and you should not put in more than 1000mls of water per kilo of plaster. Just to be safe I use about 750mls of water per kilo of plaster or in other words a total of 2250mls for the 3kg of plaster.

Put the water into your mixing bucket first, and then sprinkle the plaster over the top while stirring the mix to disperse it. That is easier to say than it is to do so in practice you might want somebody to stir for you so you can regulate the addition of the powder. Add the powder slowly and then continue stirring until the mix is homogeneous and most of the bubbles are gone. The plaster will be starting to set at this point so don’t stir for too long, a minute tops!

Carefully pour the plaster slurry into your outer mould and give it a tap around the edges to dislodge any bubbles, then float your inner mould in the centre of the outer mould and leave it. The plaster slurry should proceed to get warm and go hard over the next 20 to 40 minutes. If you check back in an hour or two and it is still not set there is something wrong and you will have to start again with a new batch of plaster. The plaster will continue to gain strength up until 24 hours after setting so leave it alone until then.

After 24 hours setting time remove the inner mould by lifting it out, clean and return it to your significant other, assuming you pulled the same trick that I did. Then push on the bottom of your outer mould until the bat comes free. The bat will need to be as dry as you can get it to work properly so set it aside in a warm dry area, I put ours in the greenhouse but if you don’t have a greenhouse the back seat of a car on a hot day works well. If you want to get techo you could weigh the bat and keep a track of its weight loss over time, when no more weight is lost after it has been in a hot environment it will be completely dry. Personally, when it feels dry to the touch, I would use it.

Have fun processing lots of clay!