This article was originally written and published under the title “In The Marketplace” in the September 1982 edition of a magazine called “Australasian Survivor” run by a friend of mine, Bill Tarplee out of Canberra. It reflects his experiences at the time of making and selling quality toys. As mentioned under my article on toymaking books, this is a great sustainable pastime when using off cuts, locally grown and/or sustainably grown or recycled timber.

The other evening I was sitting by the stove, drinking home ground coffee and reflecting upon nothing in particular. For some reason my mind went back to the time when a mate and I went into business. We came close to making a fortune too.

We had gone to our local Trash ‘n Treasure for a look about. In the course of our perambulations we tripped over a bunch of counter culturists, who were in the process of setting up a toy stall. As we untangled ourselves from the assorted toys and persons, a common idea sprang to mind. The toys were JUNK. They might have been hand crafted and they might have been made from solid wood, but they were without style, or balance or design – they were overpriced rubbish. We made our apologies, untangled ourselves and headed for home. As I recall we didn’t even discuss the idea, we just went straight to work.

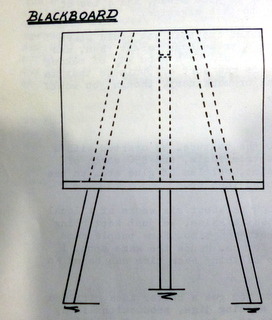

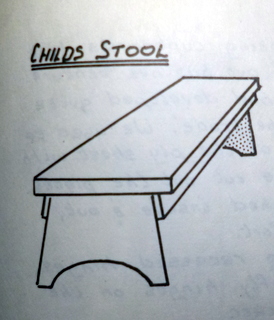

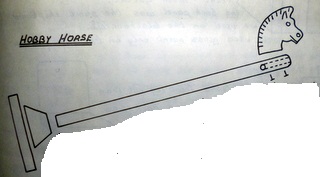

The next Sunday we were back with a load of homemade goodies. We had blackboards, hobby horses, children’s seats, a couple of raking rabbits and some blocks. All were well made; all were varnished and smooth, and all well priced. Our total expenses were under $50. Someone else had apparently tripped over as well, as we also had competition. This did not trouble us, as we felt that a bit of competition helped to keep everyone honest.

At the end of the day we had sold about $12 worth of $1 and $2 toys. It was hardly a real success. Our competition had packed it in; it was the last we ever saw of them. We just packed our trailer and went home and got back to work. The next week we were back in the marketplace with an even larger selection of toys. That week we sold about $25, which we took as a good sign, since we had doubled our sales. So we went home, ploughed in our “profits” and made more toys. The next week we sold $125 worth – in fact we sold just about everything we had with us.

WE HAD A BUSINESS!

We used to work every night after the office let us go. We worked all day Saturday, and again Sunday afternoon after the markets had closed, By working flat out we could just make sufficient toys to meet the demand on Sunday morning.

We constantly refined our production techniques. We dropped lines that didn’t sell; we looked for better ways of production. We studied ways of making a stronger product. (I recall once being told that the table and chair sets didn’t look very strong. I was confident to jump up onto a table top and walk from one top to another). We experimented constantly. We made a competition to see who could new and better construction methods, who could find an easier or quicker way of doing a particular process.

All the while, we were behind schedule. We had extra orders for toys that we could make when we found a few free minutes. Our production problems were that we just could not meet the demand. All the while we had extra ideas that we wanted to try, but could not find time for. The work load became so demanding that we could not even take the time to set up machinery that we had purchased – machinery that was supposed to save us time. It was really having the tiger by the tail! It was fortunate for us that Christmas arrived, before we blew a fuse.

Just prior to Christmas we were approached by a buyer from one of the big stores. He wanted to buy EVERYTHING that we could make. We regretfully refused as we already had far more customers than we could satisfy.

Over the Christmas period my partner moved, and the business came to a close. I couldn’t do it on my own and I couldn’t find another partner who was interested in doing any work. However, the experience has stood me in good stead.

The reason for this article is to point out that you could start such a business if you wished. There was a tremendous market then and I would assume that it still exists. This could be a good way of making the break and becoming independent. It is the sort of business that is not reliant on huge amounts of capital or machinery although you would need some power tools to be successful.

Some lessons that we learnt:

- Be prepared to put some money into the venture. We started with a shed full of hand tools, some basic electric tools and $50 worth of wood. I also had tins of varnish and paint, bottles of glue etc. on the shelf. These we replaced later as we used them up.

- Be prepared to stick it out. It took us about 6 weeks at a local market before we started to make worthwhile sales. We just kept going back and we tried to be in the same spot each time. Some people came back after 6 to 8 weeks looking for us. Hence the same spot. I am of the opinion that wearing the same clothing each time can be of an advantage too.

- Keep looking for better ideas. Once you get a better idea, try and improve upon it. We used cutting jigs, sanding jigs, production lines, spray lines – anything to better the job at a faster rate. There were all logical extensions of “time and motion”, getting the best out of an available piece of time.

- Above all we kept our prices low and our quality high. We succeeded in underselling all our competitors, and with a better product.

- Once we could see that we were on a winner, we were prepared to back it with money, I bought hundreds of dollars worth of tools for the next year’s production. While we never got to use them commercially, I now have a good workshop that I use to make my own furniture.

- We simplified out designs constantly. We looked for better shapes, cleaner lines, and better appearance.

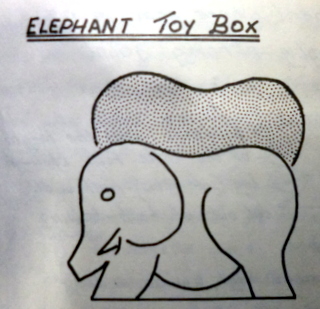

- We refused to make dangerous toys. We had a range of toy boxes on castors. We refused to fit the boxes with lids, as we considered them to be dangerous. We lost a few sales, but I think people appreciated our honesty in refusing the lidded version.

- We kept looking for cheaper sources of raw materials. Toward the end, we bought our timber from the local mill, our ply from the ply mill and our varnish from the manufacturer. We went around the middle men. Our profits increased through saving expenses, not raising process.

- We were prepared to accept a 1% profit at the outset. In fact on some lines we lost money at the outset. With thought and planning all were eventually profitable.

I have given some of the designs that we used, for us the designs were very successful. The work processes were kept to a minimum. You can adapt the designs to your own requirements if you wish. I think the time is ripe for such a venture, the Christmas market is approaching and well made, well priced toys always sell. This could be your way out of the rat race.

The designs that Bill included with this article can be found here.